Digital Twin Solution for CO Gas Pipeline Safety in Steel Plants

In steel plants, carbon monoxide (CO) pipelines are critical, but any leak could lead to hazardous situations. VB Group’s innovative Digital Twin technology provides an advanced digital replica of CO gas pipelines, enabling operators to monitor every inch in real-time and respond proactively to any threat.

Features Overview

Some of the Features that are gonna blow your mind offPredictive Safety Management

The Digital Twin simulates pipeline behaviour, anticipating potential failures before they occur. By analyzing real-time sensor data and historical trends, it helps prevent leaks and system faults.

Real-Time Leak Detection

Integrated IoT sensors continuously feed pressure, flow, and gas concentration metrics. The digital twin instantly spots anomalies, such as unexpected pressure drops, triggering immediate alerts.

Intelligent Incident Response

In emergencies, operators view the exact location and severity of issues on a digital model. Automated systems can trigger isolation protocols and guide field teams, minimizing response times and damage.

Risk Reduction & Personnel Safety

The system swiftly identifies issues and triggers targeted responses reducing personnel risk, preventing downtime, and avoiding costly asset damage.

Centralized Monitoring & Control

Stay in control from anywhere. All digital twin models and alerts can be accessed via a centralized dashboard locally or remotely. With role based access and integration with mobile devices, plant managers, safety officers, and maintenance teams stay informed and ready to act.

1. 24/7 monitoring from control room or mobile devices

2. Multi-plant dashboard for enterprise-wide safety

3. Cloud or on-premise deployment flexibility

Why Choose Wistwin?

VB Group has successfully implemented this solution across multiple steel plant sites.

VB has developed a cutting edge Digital Twin solution to monitor and ensure the safety of CO gas pipelines in steel plants. This real time digital replica enables:

- Predictive safety management

- Real time leak detection

- Intelligent incident response

- Reduced risks to personnel and infrastructure

How it Works

Here are 3 key steps in how it works:

Step 1: Real-Time Data Collection with IoT Sensors - CO pipelines are equipped with advanced IoT sensors that constantly measure key parameters like gas pressure, flow rate, and CO concentration.

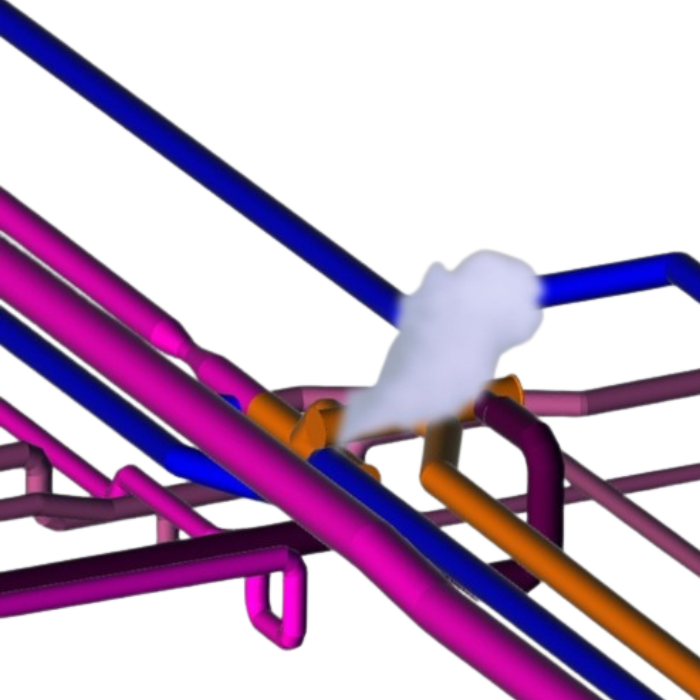

Step 2: Digital Twin Simulation & Anomaly Detection - The real-time data feeds into a virtual Digital Twin—an exact digital replica of the pipeline. Machine learning algorithms analyze this data to simulate behavior, detect anomalies, and predict potential issues.

Step 3: Automated Alerts & Guided Response - When an issue is detected, the system instantly sends alerts and generates response actions. These include valve shutdowns, evacuation alerts, and live fault location mapping for operators.